The foil is plated on the top side with solder, and an epoxy bonding film is applied to the bottom side. Note: New conductors are fabricated from copper foil. If a special size or shape is needed, it can be custom fabricated. Select a replacement circuit with film adhesive backing that most closely matches the size of the conductor to be replaced.The length of the overlap solder connection should be a minimum of 2 times the circuit width.

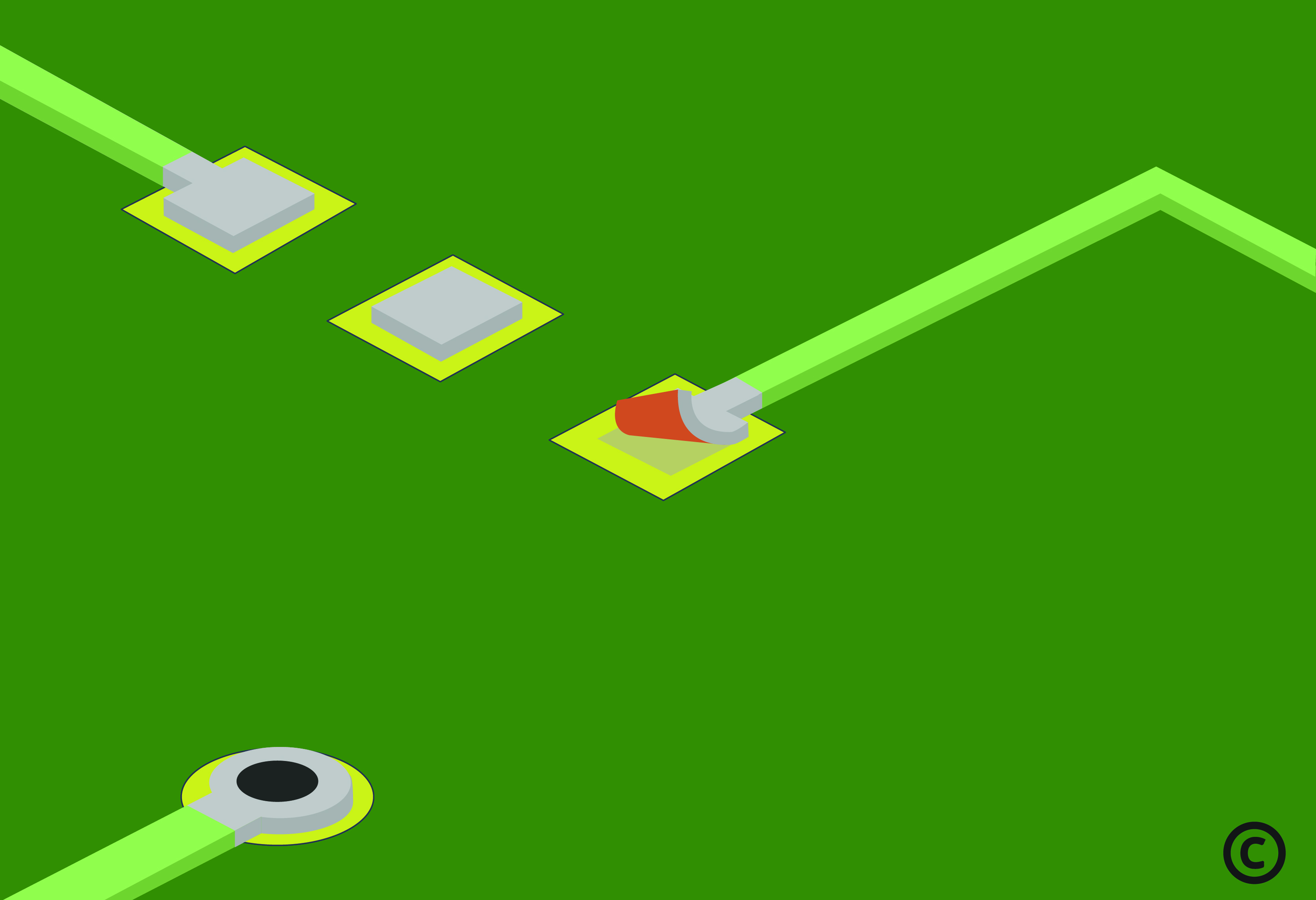

Apply a small amount of liquid flux to the connection area on the board surface and tin with solder.Scrape off any solder mask or coating from the connecting circuit.Use the knife and scrape off any epoxy residue, contamination, or burned material from the board surface.The damaged circuit should be trimmed back to a point where the circuit still has a good bond to the PC board surface. Remove the damaged section of the circuit using the knife.This procedure most closely duplicates the physical characteristics of the original, and most probably complies with all the functional, environmental and serviceability factors.Ĭonductor Repair, Foil Jumper, Film Adhesive Method Recommended for technicians with soldering and component rework skills and exposure to most repair/rework procedures, but lacking extensive experience. If the baseboard is damaged see appropriate procedure. Caution: It is essential that the board surface be extremely smooth and flat.

This method is used to replace damaged or missing circuits on the circuit board surface. To view this video please enable JavaScript, and consider upgrading to a web browser that supports HTML5 video.

0 kommentar(er)

0 kommentar(er)